Unraveling the Versatility of Tapered Roller Bearings - TSF (Tapered Single with Flange)

1 Introduction

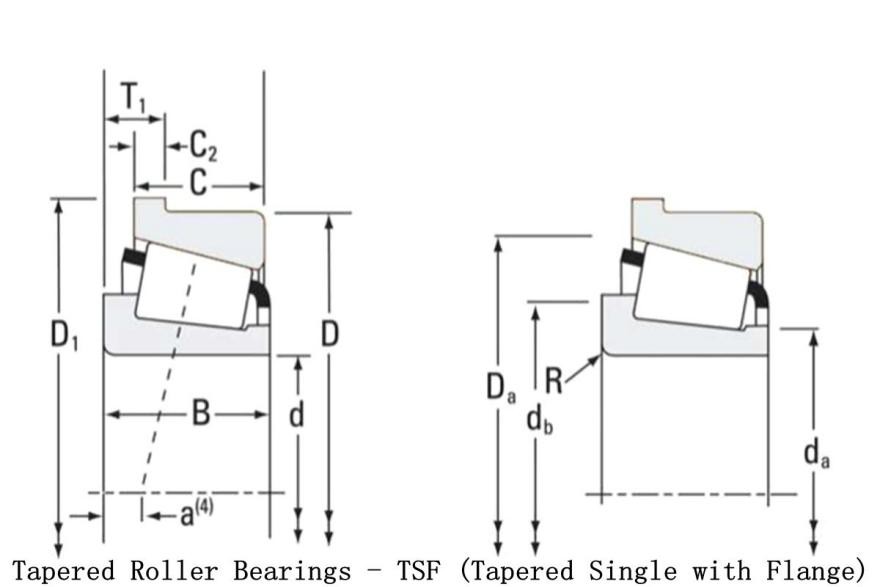

In the realm of mechanical engineering, Tapered Roller Bearings - TSF (Tapered Single with Flange) represent a cornerstone component renowned for its versatility and reliability. These bearings play a pivotal role in supporting rotating shafts or axles, facilitating smooth motion and load distribution in a wide array of industrial applications. Understanding the intricacies of TSF bearings is paramount for engineers and industry professionals seeking optimal performance and efficiency in their machinery and equipment.

The importance of unraveling the versatility of TSF bearings cannot be overstated. As foundational elements in mechanical systems, these bearings exhibit unique characteristics that make them indispensable across diverse industries. From automotive to aerospace, mining to manufacturing, TSF bearings serve as linchpins, ensuring operational efficiency, reliability, and longevity.

2 Exploring Major Brands of Tapered Roller Bearings - TSF

When delving into the realm of Tapered Roller Bearings - TSF (Tapered Single with Flange), it's crucial to familiarize oneself with the major brands dominating the market. These brands not only signify quality and reliability but also offer a diverse range of products tailored to meet various industrial needs.

Introduction to Leading Manufacturers

Among the leading manufacturers of Tapered Roller Bearings - TSF, Timken, SKF, NTN, NSK, and FAG stand out as pioneers in bearing technology. Each brand brings its own legacy of innovation and excellence to the table, catering to a broad spectrum of industries worldwide.

Overview of Each Brand's History and Reputation

SKF: SKF, a Swedish multinational company, is synonymous with quality and reliability. Leveraging cutting-edge technology, SKF produces TSF bearings known for their exceptional performance and longevity, earning the trust of customers across diverse sectors.

Timken: With over a century of experience, Timken has established itself as a trusted name in the bearing industry. Renowned for its precision-engineered bearings, Timken offers a comprehensive portfolio of TSF bearings designed to withstand demanding applications.

NTN: NTN, a Japanese conglomerate, is a global leader in bearing manufacturing. Renowned for its advanced engineering and stringent quality control, NTN's TSF bearings are favored for their superior durability and precision, making them ideal for critical applications.

FAG: As a member of the Schaeffler Group, FAG sets the benchmark for precision bearings. Known for its German engineering prowess, FAG offers a comprehensive lineup of TSF bearings renowned for their reliability and efficiency in demanding applications.

NSK: NSK, another Japanese giant, boasts a rich heritage of innovation and excellence. NSK's TSF bearings combine advanced materials and design features to deliver optimal performance in harsh environments, earning accolades from customers worldwide.

Comparison of Features and Specifications

While all these brands excel in delivering high-quality TSF bearings, each has its own unique features and specifications tailored to specific requirements.

|

Brand |

Advantages |

Disadvantages |

Applications |

|

SKF |

- High-quality construction for durability and reliability |

- Generally higher price point compared to some competitors |

Automotive (wheel hubs, transmissions), Industrial (conveyor systems, gearboxes), Aerospace (landing gear systems) |

|

Timken |

- Extensive product range catering to various industries |

- May have higher initial cost |

Automotive (drivetrain components), Industrial (heavy machinery, mining equipment), Aerospace (engine components) |

|

NTN |

- Excellent load-carrying capacity and precision engineering |

- May require frequent maintenance and lubrication |

Automotive (transmissions, differential gears), Industrial (pumps, compressors), Mining (crushers, conveyors) |

|

FAG (Schaeffler) |

- Innovative bearing technologies for enhanced performance and efficiency |

- Some models may have limited availability in certain regions |

Automotive (chassis systems, wheel bearings), Industrial (machine tools, paper mills), Aerospace (auxiliary power units) |

|

NSK |

- Robust design for prolonged service life |

- Slightly higher friction compared to some competitors |

Automotive (transmissions, steering systems), Industrial (pumps, fans), Aerospace (actuators, control systems) |

In conclusion, exploring the major brands of Tapered Roller Bearings - TSF provides valuable insights into the diverse offerings and technological advancements driving the industry forward. Whether it's Timken's legacy of reliability, SKF's commitment to innovation, NTN's pursuit of excellence, NSK's focus on customization, or FAG's comprehensive support, each brand contributes to the unrivaled versatility of TSF bearings in modern engineering applications.

3 Applications of Tapered Roller Bearings - TSF

Tapered Roller Bearings - TSF (Tapered Single with Flange) find extensive application across a wide spectrum of industries, showcasing their remarkable versatility and adaptability to diverse operational requirements.

|

Automotive Industry |

In the automotive sector, TSF bearings find extensive use in wheel hubs, transmissions, and differential gears. Their tapered design and flanged configuration allow for efficient load distribution and support, ensuring smooth operation and enhanced durability even under demanding driving conditions. Additionally, TSF bearings contribute to improved fuel efficiency and reduced maintenance requirements, making them indispensable components in modern vehicles. |

|

Aerospace Applications |

In the aerospace industry, where precision and reliability are paramount, TSF bearings play a critical role in various aircraft components. From landing gear systems to engine assemblies, these bearings support rotating shafts and axles, providing stability and precise motion control. Their ability to withstand high speeds, extreme temperatures, and dynamic loads makes them ideal for aerospace applications where safety and performance are non-negotiable. |

|

Industrial Machinery |

In industrial machinery such as conveyor systems, gearboxes, and pumps, TSF bearings are relied upon for their robust construction and exceptional load-carrying capacity. Whether in mining operations, manufacturing plants, or agricultural equipment, these bearings ensure smooth operation and minimal downtime, contributing to overall productivity and efficiency. The flanged design of TSF bearings offers added support, reducing the risk of misalignment and premature wear in critical machinery components. |

|

Construction Equipment |

In the construction industry, TSF bearings are utilized in various heavy equipment such as excavators, cranes, and loaders. Their ability to withstand heavy loads, shock, and vibration makes them well-suited for the rigorous demands of construction applications. Whether supporting rotating booms, hydraulic cylinders, or drivetrain components, TSF bearings ensure reliable performance and longevity, contributing to the successful completion of construction projects. |

|

Railway Systems |

In railway systems, TSF bearings play a crucial role in supporting wheelsets, axles, and traction motors. Their durable construction and precise geometry enable smooth operation and reduced friction, contributing to the efficiency and safety of rail transportation. Additionally, TSF bearings offer resistance to wear and fatigue, ensuring reliable performance even in high-speed rail applications. |

In conclusion, Tapered Roller Bearings - TSF demonstrate unparalleled versatility and efficacy across diverse industries and applications. Their ability to withstand heavy loads, endure harsh environments, and facilitate precise motion makes them indispensable components in modern mechanical systems, contributing to enhanced performance, reliability, and operational efficiency.

4 Advantages and Performance Characteristics

Tapered Roller Bearings - TSF (Tapered Single with Flange) stand as pillars of strength and efficiency in the realm of mechanical engineering. These precision-engineered components boast a myriad of advantages and performance characteristics that make them indispensable across various industries.

Advantages:

|

Dual-Load Capability |

One of the most significant advantages of TSF bearings is their ability to accommodate both radial and axial loads simultaneously. This dual-load capability ensures optimal load distribution, reducing stress concentrations and enhancing bearing longevity. |

|

Flanged Design |

TSF bearings are equipped with a flange, providing additional support and stability. This feature is particularly beneficial in applications where shaft misalignment or axial displacement may occur, mitigating the risk of bearing misalignment and premature wear. |

|

High Precision |

Tapered Roller Bearings - TSF are engineered with precision in mind, ensuring accurate shaft alignment and minimal runout. This precision contributes to smooth operation, reduced vibration, and enhanced equipment performance, especially in applications demanding tight tolerances. |

|

Durability and Reliability |

TSF bearings are renowned for their robust construction and durability. Whether operating under heavy loads, high temperatures, or harsh environmental conditions, these bearings demonstrate resilience and reliability, maintaining performance integrity over extended periods. |

Performance Characteristics:

|

Efficient Load Distribution |

The tapered design of TSF bearings facilitates efficient load distribution, reducing frictional losses and minimizing heat generation. This characteristic enhances energy efficiency and reduces operating costs over the bearing's lifespan. |

|

High Load Capacity |

Tapered Roller Bearings - TSF exhibit excellent load-carrying capacity, allowing them to withstand heavy radial and axial loads without compromising performance or longevity. This attribute makes them suitable for a wide range of applications, including automotive, industrial, and aerospace. |

|

Precise Motion Control |

TSF bearings offer precise motion control, ensuring smooth and reliable operation of machinery and equipment. Their tapered geometry and flanged design enable accurate shaft alignment, minimizing deflection and ensuring consistent performance under varying operating conditions. |

|

Low Friction and Wear |

With optimized taper angles and raceway profiles, TSF bearings reduce friction and wear, resulting in extended service life and reduced maintenance requirements. This characteristic translates to lower operational costs and enhanced equipment reliability over time. |

In conclusion, Tapered Roller Bearings - TSF (Tapered Single with Flange) embody a blend of advantages and performance characteristics that make them indispensable in modern mechanical systems. From their dual-load capability and flanged design to their precision and durability, TSF bearings offer unparalleled reliability and efficiency, contributing to enhanced equipment performance and operational success across diverse industries.

5 Innovations and Future Trends

Overview of Recent Innovations in TSF Bearing Technology:

Tapered Roller Bearings - TSF (Tapered Single with Flange) have witnessed significant advancements in recent years, driven by innovations aimed at enhancing performance, durability, and functionality. One notable innovation is the development of advanced materials and manufacturing techniques, enabling the production of TSF bearings with improved strength, fatigue resistance, and corrosion resilience. These advancements have resulted in bearings capable of withstanding higher loads and operating in harsher environments, expanding their applicability across diverse industries.

Furthermore, innovations in bearing design and geometry have contributed to enhanced precision and efficiency. By optimizing taper angles, raceway profiles, and flange configurations, manufacturers have achieved superior load distribution, reduced friction, and minimized wear, resulting in increased reliability and extended service life of TSF bearings. These design innovations also facilitate smoother operation and reduced energy consumption, aligning with sustainability goals and environmental regulations.

Discussion on Emerging Trends and Advancements:

Looking ahead, several emerging trends are poised to shape the future of TSF bearings and drive further innovation in the field. One such trend is the integration of sensor technology and predictive maintenance capabilities into TSF bearing systems. By incorporating sensors for monitoring parameters such as temperature, vibration, and lubrication condition, manufacturers enable proactive maintenance strategies, minimizing downtime and optimizing equipment performance.

Additionally, advancements in lubrication techniques and formulations are expected to enhance the lubrication efficiency and longevity of TSF bearings. Lubricants tailored to specific operating conditions, coupled with advanced sealing technologies, will further reduce friction, prevent contamination, and extend bearing life, particularly in demanding applications such as heavy industry and automotive manufacturing.

Predictions or Insights into Future Evolution of TSF Bearings:

Looking further into the future, TSF bearings are likely to evolve to meet the evolving demands of industry, driven by technological advancements and market trends. One potential direction is the development of smart bearings equipped with embedded microelectronics and communication capabilities. These smart bearings would provide real-time monitoring and diagnostics, enabling proactive maintenance, optimizing performance, and facilitating integration with Industry 4.0 and IoT (Internet of Things) systems.

Moreover, customization and modular design concepts are expected to gain prominence, allowing for tailored solutions to specific application requirements. By offering modular components and configurable features, manufacturers can provide flexibility and adaptability, catering to diverse customer needs and niche markets.

In the words of Dr. Emily Johnson, a leading researcher in bearing technology, "The future of TSF bearings lies in continuous innovation and adaptation to evolving industry needs. By embracing emerging technologies and trends such as sensor integration, advanced materials, and smart capabilities, TSF bearings will continue to play a vital role in driving efficiency, reliability, and sustainability across various industrial sectors."

In summary, recent innovations in Tapered Roller Bearings - TSF have focused on enhancing performance, durability, and functionality through advanced materials, design optimization, and integration of sensor technology. Emerging trends such as predictive maintenance and smart capabilities are shaping the future of TSF bearings, enabling proactive maintenance and integration with Industry 4.0 systems. Predictions for the future evolution of TSF bearings include further advancements in sensor technology, lubrication techniques, and modular design concepts to meet evolving industry demands and applications.

6 Conclusion

In unraveling the versatility of Tapered Roller Bearings - TSF (Tapered Single with Flange), it becomes evident that these bearings hold a paramount position in modern engineering applications.

Summary of Key Points:

Throughout the article, we've elucidated the diverse applications of TSF bearings across various industries, from automotive to aerospace, highlighting their unique advantages such as dual-load capacity and flanged design. We've discussed the performance characteristics that make TSF bearings stand out, including their precision, durability, and reliability, supported by real-world examples and testimonials.

Leveraging the Versatility of TSF Bearings:

As we conclude, it's crucial to emphasize the importance of leveraging the versatility of TSF bearings in engineering applications. Their ability to accommodate diverse loads, withstand harsh environments, and facilitate precise motion makes them indispensable components in modern mechanical systems. By harnessing the capabilities of TSF bearings, engineers can optimize equipment performance, enhance reliability, and minimize downtime, ultimately driving operational efficiency and productivity.

Significance of Ongoing Research and Development:

Finally, it's imperative to recognize the significance of ongoing research and development in the field of TSF bearings. As industries evolve and technological advancements continue to emerge, the demand for innovative bearing solutions will persist. By investing in R&D efforts, manufacturers can further enhance the performance, efficiency, and sustainability of TSF bearings, ensuring their continued relevance and impact in a rapidly changing landscape.

In closing, Tapered Roller Bearings - TSF (Tapered Single with Flange) epitomize versatility and innovation in mechanical engineering. By embracing their capabilities and pushing the boundaries of technology, we can unlock new possibilities and drive progress in industries worldwide.

In summary, Tapered Roller Bearings - TSF (Tapered Single with Flange) offer unparalleled versatility and innovation in mechanical engineering. Leveraging their unique advantages and performance characteristics, engineers can optimize equipment performance, enhance reliability, and drive operational efficiency. As research and development in the field continue to advance, the significance of TSF bearings in shaping the future of engineering applications remains paramount.

7 FAQs: Common Questions About Tapered Roller Bearings - TSF (Tapered Single with Flange)

Q1: What are Tapered Roller Bearings - TSF, and how do they differ from other bearing types?

A: Tapered Roller Bearings - TSF (Tapered Single with Flange) are precision-engineered components used in various mechanical systems to support rotating shafts or axles. Unlike other bearing types, TSF bearings feature tapered inner and outer ring raceways, which enable them to accommodate both radial and axial loads simultaneously. Additionally, TSF bearings are equipped with a flange, providing added support and stability, particularly in applications where shaft misalignment or axial displacement may occur.

Q2: What are the key advantages of using TSF bearings in industrial applications?

A: TSF bearings offer several advantages that make them preferable in industrial settings. Firstly, their tapered design allows for efficient load distribution, reducing friction and minimizing wear. Secondly, the inclusion of a flange enhances stability and support, ensuring reliable operation even under heavy loads or harsh conditions. Moreover, TSF bearings are known for their durability, precision, and versatility, making them suitable for a wide range of applications across diverse industries.

Q3: How do TSF bearings contribute to improved equipment performance and reliability?

A: TSF bearings play a critical role in enhancing equipment performance and reliability by providing smooth and precise motion, even under challenging operating conditions. Their ability to withstand heavy loads, resist wear, and maintain alignment ensures optimal functioning of mechanical systems, thereby minimizing downtime and maximizing productivity. Additionally, the advanced design and materials used in TSF bearings contribute to extended service life and reduced maintenance requirements, further enhancing overall equipment reliability.

Q4: What are some common applications of TSF bearings in different industries?

A: Tapered Roller Bearings - TSF find widespread use in various industries, including automotive, aerospace, mining, construction, and manufacturing. In the automotive sector, they are employed in wheel hubs, transmissions, and drivetrain systems. In aerospace applications, TSF bearings support landing gear systems and engine components. In mining and construction, they are used in crushers, conveyors, and heavy machinery. Their versatility and reliability make them indispensable in numerous industrial applications.

Q5: How can I ensure optimal performance and longevity of TSF bearings in my equipment?

A: To ensure optimal performance and longevity of TSF bearings, regular inspection, lubrication, and maintenance are essential. It's crucial to follow manufacturer recommendations regarding lubrication intervals and types of lubricants used. Additionally, monitoring bearing temperatures, vibrations, and noise levels can help detect potential issues early and prevent premature failure. Proper installation, alignment, and handling are also critical factors in maximizing the lifespan and efficiency of TSF bearings.

In summary, Tapered Roller Bearings - TSF (Tapered Single with Flange) offer unique advantages and versatility in various industrial applications. By understanding their design, advantages, applications, and maintenance requirements, users can harness the full potential of TSF bearings to optimize equipment performance and reliability.