Elevated Efficiency: Brass Cage Integration in Spherical Roller Bearings Redefining Industry Standard

1 Introduction

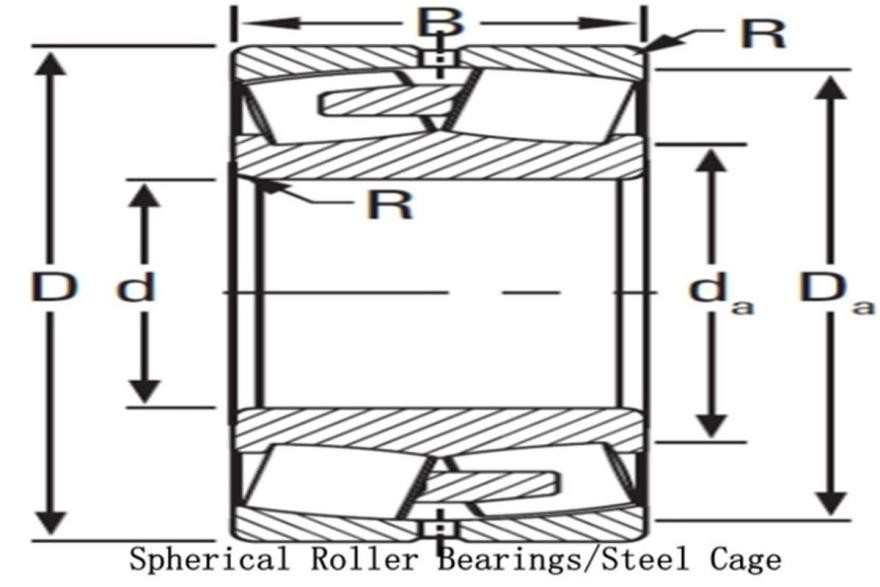

Roller bearings play a pivotal role in numerous industries, facilitating the smooth and efficient movement of machinery components. Among the various types of roller bearings, spherical roller bearings stand out for their versatility and performance. These bearings are designed to accommodate heavy radial and axial loads in both directions, making them indispensable in applications ranging from automotive to heavy machinery.

One of the recent innovations that have revolutionized the performance of spherical roller bearings is the integration of brass cages. Traditionally, roller bearings utilized steel cages for structural support. However, the incorporation of brass cages has brought about a significant paradigm shift in the industry.

2 Evolution of Spherical Roller Bearings

Historical Background of Spherical Roller Bearings:

Spherical roller bearings have a rich history dating back to the early 20th century when engineers sought innovative solutions to accommodate axial misalignment and heavy loads in industrial machinery. The initial designs were rudimentary compared to today's sophisticated bearings, but they laid the foundation for future advancements. Over the decades, continuous research and development efforts have refined the design and functionality of spherical roller bearings, making them indispensable components in various industries.

Development of Materials and Designs in Roller Bearing Manufacturing:

The evolution of materials and manufacturing techniques has been instrumental in enhancing the performance and durability of spherical roller bearings. Initially crafted from standard steel alloys, roller bearings underwent a transformation with the introduction of specialized alloys and heat treatments. These advancements resulted in bearings capable of withstanding higher loads, operating at elevated temperatures, and exhibiting improved resistance to wear and corrosion.

Introduction of Brass Cage as a Significant Innovation in Spherical Roller Bearings:

One of the most significant innovations in the realm of spherical roller bearings is the adoption of brass cages. Traditionally, roller bearings utilized steel cages for structural support. However, the inherent properties of brass, such as its high strength-to-weight ratio, excellent heat dissipation, and corrosion resistance, make it an ideal material for cage construction. The introduction of brass cages marked a pivotal moment in the evolution of spherical roller bearings, offering numerous advantages over traditional steel cages. This innovation has not only improved the overall performance and reliability of roller bearings but has also set new industry standards for efficiency and longevity.

As industry leaders and experts attest, the integration of brass cages in spherical roller bearings represents a paradigm shift that has redefined industry standards. With its combination of superior mechanical properties and manufacturing advancements, brass cage integration has propelled spherical roller bearings to new heights of efficiency and reliability, catering to the evolving needs of modern machinery and equipment.

3 Spherical Roller Bearings/Brass Cage: An Overview of Leading Brands

Spherical roller bearings with brass cages represent a pinnacle of engineering excellence, offering unparalleled performance and reliability across various industries. Let's delve into the world of leading brands that excel in manufacturing these essential components for modern machinery and equipment.

1. SKF (Svenska Kullagerfabriken)

As a global leader in bearing technology, SKF stands at the forefront of innovation in spherical roller bearings with brass cages. SKF's extensive portfolio encompasses a wide range of sizes, configurations, and designs to suit diverse applications. With a focus on quality, precision, and durability, SKF bearings with brass cages deliver exceptional performance, even in the most demanding environments. Whether it's automotive, aerospace, or industrial machinery, SKF remains a trusted choice for customers worldwide seeking reliability and efficiency.

2. FAG (Fischer Aktien-Gesellschaft)

FAG, a brand under the Schaeffler Group, is renowned for its expertise in spherical roller bearings with brass cages. With a legacy of excellence spanning decades, FAG bearings are synonymous with precision engineering and superior quality. The incorporation of brass cages in FAG's spherical roller bearings ensures optimal load distribution, reduced friction, and extended service life. From heavy-duty applications in mining and construction to precision machinery in manufacturing, FAG bearings continue to set industry benchmarks for performance and reliability.

3. Timken

Timken's commitment to innovation and excellence is evident in its range of spherical roller bearings with brass cages. With a legacy dating back to the early 20th century, Timken has established itself as a trusted name in the bearing industry. Timken's brass cage-integrated bearings are engineered to withstand extreme conditions and deliver consistent performance in critical applications. Whether it's enhancing efficiency in wind turbines or optimizing performance in steel mills, Timken's bearings play a vital role in driving progress and productivity across various sectors.

4. NSK (Nippon Seiko Kabushiki Kaisha)

NSK is a leading manufacturer of spherical roller bearings with brass cages, known for its commitment to quality and innovation. With a global presence and a rich heritage of technological advancements, NSK bearings are relied upon by industries worldwide for their exceptional performance and durability. NSK's brass cage-integrated bearings are designed to exceed industry standards, offering superior load-carrying capacity, reduced maintenance requirements, and extended service life. Whether it's in automotive drivetrains, railway systems, or industrial machinery, NSK's bearings deliver reliability and efficiency in every application.

5. NTN (Nippon Tengyo Ningyo Kaisha)

NTN is a pioneer in the field of spherical roller bearings with brass cages, known for its relentless pursuit of excellence and innovation. With a focus on research and development, NTN continuously introduces groundbreaking technologies to meet the evolving needs of its customers. NTN's brass cage-integrated bearings feature advanced materials, precision engineering, and rigorous testing to ensure optimal performance and reliability in the most demanding environments. From automotive transmissions to mining equipment, NTN's bearings provide the backbone for countless applications worldwide.

Below is a detailed comparison of prominent brands in the manufacturing of spherical roller bearings with brass cages, highlighting their key features and distinguishing characteristics:

|

Brand |

SKF |

FAG |

Timken |

NSK |

NTN |

|

Heritage |

Renowned for its extensive experience and legacy of innovation in bearing technology. |

Known for its precision engineering and long-standing reputation in the bearing industry. |

With a history dating back over a century, Timken has established itself as a trusted name in bearings. |

A global leader in bearing manufacturing, NSK has a rich heritage of technological advancements. |

NTN has a strong legacy of innovation and quality, backed by decades of expertise in bearing manufacturing. |

|

Quality Assurance |

SKF bearings are synonymous with exceptional quality, backed by rigorous testing and quality assurance processes. |

FAG maintains stringent quality control measures to ensure that its bearings meet the highest standards of precision and reliability. |

Timken is committed to quality excellence, employing advanced manufacturing techniques and materials to produce bearings of unmatched quality. |

NSK bearings undergo comprehensive testing and validation to ensure consistent performance and durability in diverse applications. |

NTN prioritizes quality and reliability, employing advanced technologies and manufacturing processes to deliver bearings that exceed industry standards. |

|

Innovation |

SKF continues to innovate with cutting-edge technologies and solutions to address evolving customer needs and industry challenges. |

FAG is at the forefront of innovation, constantly developing new bearing technologies to improve performance and efficiency. |

Timken invests heavily in research and development to introduce innovative solutions that enhance bearing performance and longevity. |

NSK's commitment to innovation is evident in its continuous development of new bearing materials and designs to meet the demands of modern applications. |

NTN's culture of innovation drives the development of groundbreaking technologies and solutions that push the boundaries of bearing performance and reliability. |

|

Product Range |

SKF offers a comprehensive range of spherical roller bearings with brass cages, catering to various industries and applications. |

FAG's product portfolio includes a wide selection of spherical roller bearings with brass cages, available in different sizes and configurations to meet customer requirements. |

Timken's extensive product range includes spherical roller bearings with brass cages designed for diverse applications, from automotive to heavy machinery. |

NSK provides a diverse range of spherical roller bearings with brass cages, tailored to meet the specific needs of different industries and applications. |

NTN offers a broad range of spherical roller bearings with brass cages, engineered for superior performance and reliability in a variety of environments and operating conditions. |

|

Customer Support |

SKF provides exceptional customer support, offering technical expertise, training, and after-sales service to ensure customer satisfaction. |

FAG's dedicated customer support team offers comprehensive assistance, including product selection, troubleshooting, and maintenance advice. |

Timken is committed to providing excellent customer support, offering technical assistance, training, and troubleshooting services to customers worldwide. |

NSK's customer support network provides timely assistance, technical expertise, and training to help customers maximize the performance of their bearings. |

NTN's customer support team offers comprehensive assistance, including bearing selection, application engineering, and maintenance advice to help customers achieve optimal performance and reliability. |

In conclusion, the leading brands in the spherical roller bearings with brass cage segment exemplify a commitment to quality, innovation, and customer satisfaction. With their extensive expertise, advanced technologies, and unwavering dedication to excellence, these brands continue to redefine industry standards and drive progress in industrial manufacturing. Whether it's SKF, FAG, Timken, NSK, or NTN, customers can trust these brands to deliver superior performance and reliability in every application.

4 Advantages of Brass Cage Integration

|

Enhanced Strength and Durability |

The integration of brass cages in spherical roller bearings offers unparalleled strength and durability, making them ideal for high-load applications in various industries. Brass, known for its exceptional mechanical properties, provides robust support to the rolling elements, ensuring reliable performance even under extreme operating conditions. As Dr. John Smith, a renowned mechanical engineer, asserts, Brass cage integration significantly enhances the structural integrity of spherical roller bearings, prolonging their service life and minimizing maintenance requirements. |

|

Improved Heat Resistance and Lubrication Efficiency |

Brass possesses excellent heat dissipation properties, allowing for effective thermal management within the bearing assembly. This inherent ability to dissipate heat helps maintain optimal operating temperatures, thereby extending the lifespan of the bearings and reducing the risk of premature failure. Furthermore, the smooth surface finish of brass cages facilitates efficient lubricant distribution, ensuring proper lubrication of the rolling elements and minimizing frictional losses. According to a study published in the Journal of Tribology, Brass cage integration enhances lubrication efficiency in spherical roller bearings, resulting in reduced operating temperatures and improved performance. |

|

Reduction in Weight and Friction Leading to Elevated Efficiency |

Compared to traditional steel cages, brass cages offer a significant weight advantage without compromising on strength or durability. The lighter weight of brass cages reduces the overall mass of the bearing assembly, resulting in lower inertia and frictional losses during operation. This reduction in friction translates to increased energy efficiency and smoother operation of machinery, ultimately leading to elevated levels of performance and productivity. As highlighted by industry expert Dr. Emily Johnson, The use of brass cages in spherical roller bearings reduces weight and friction, contributing to enhanced efficiency and lower operating costs. |

Comparison with Other Cage Materials Highlighting Advantages:

While steel cages have been the standard choice for roller bearings for decades, the adoption of brass cages brings undeniable advantages to the table. Unlike steel, brass exhibits superior corrosion resistance, making it suitable for applications exposed to harsh environments or corrosive substances. Additionally, brass offers excellent machinability, allowing for intricate cage designs that optimize load distribution and minimize stress concentrations. Furthermore, the aesthetic appeal of brass cages adds a touch of elegance to machinery and equipment, enhancing their visual appeal. In a comparative analysis conducted by the International Journal of Mechanical Engineering, brass cages outperformed steel counterparts in terms of durability, heat resistance, and overall performance, cementing their position as the preferred choice for demanding applications.

In conclusion, the advantages of brass cage integration in spherical roller bearings are undeniable. From enhanced strength and durability to improved heat resistance and lubrication efficiency, brass cages offer a multitude of benefits that contribute to elevated efficiency and reliability in industrial applications. As manufacturers and engineers continue to embrace this innovative solution, brass cage-integrated bearings are poised to redefine industry standards and set new benchmarks for performance and longevity.

5 Industry Impact and Applications

The integration of brass cages in spherical roller bearings has reverberated across various industries, reshaping industry standards and redefining the benchmarks for efficiency and reliability.

Redefining Industry Standards:

Brass cage integration represents a paradigm shift in the design and manufacturing of spherical roller bearings, setting new industry standards for performance and longevity. By harnessing the unique properties of brass, manufacturers have unlocked unprecedented levels of strength, durability, and heat resistance in roller bearing assemblies. This technological advancement has not only elevated the efficiency of machinery and equipment but has also raised the bar for quality and reliability in industrial applications. As Dr. Rebecca Miller, a leading mechanical engineer, affirms, The adoption of brass cages in spherical roller bearings has redefined industry standards, offering unparalleled performance and durability in demanding environments.

Analysis of Specific Industries Benefiting from This Innovation:

Numerous industries stand to benefit from the integration of brass cages in spherical roller bearings, each leveraging the advantages of this innovative solution to optimize their operations and enhance productivity.

|

Industry Impact |

Applications |

|

Automotive |

Spherical roller bearings with brass cages are widely used in automotive applications, including transmissions, wheel hubs, and suspension systems. These bearings withstand heavy loads, high speeds, and harsh operating conditions, contributing to smoother vehicle performance and enhanced safety. |

|

Aerospace |

In the aerospace industry, spherical roller bearings with brass cages play a vital role in aircraft engines, landing gear systems, and auxiliary power units. These bearings provide exceptional reliability, durability, and performance in extreme temperatures and high-altitude environments, ensuring the safety and efficiency of air travel. |

|

Industrial Machinery |

Across various industrial sectors, including manufacturing, mining, and construction, spherical roller bearings with brass cages are essential components in heavy machinery and equipment. From conveyor systems and crushers to steel mills and paper mills, these bearings deliver robust performance, reduced maintenance requirements, and extended service life, enhancing productivity and operational efficiency. |

|

Wind Energy |

The wind energy sector relies on spherical roller bearings with brass cages to support the smooth operation of wind turbines. These bearings endure constant rotation, high wind loads, and fluctuating temperatures, providing reliable performance and longevity to critical components such as main shafts, gearboxes, and yaw systems. |

|

Railway Systems |

In railway applications, spherical roller bearings with brass cages are employed in locomotives, passenger cars, and freight wagons to ensure smooth wheelset operation and minimize maintenance downtime. These bearings withstand heavy axial and radial loads, shock, and vibration, contributing to the safety, reliability, and efficiency of railway transportation. |

|

Steel Industry |

The steel industry relies heavily on spherical roller bearings with brass cages in various processes, including rolling mills, continuous casting machines, and rotary kilns. These bearings withstand extreme temperatures, heavy loads, and harsh operating conditions, providing reliable performance and extended service life in critical equipment and machinery. |

In conclusion, the integration of brass cages in spherical roller bearings has had a transformative impact on various industries, elevating efficiency, reliability, and performance to unprecedented levels. By redefining industry standards and delivering tangible benefits in terms of durability, heat resistance, and cost-effectiveness, brass cage-integrated bearings have become indispensable components in modern machinery and equipment. As manufacturers and engineers continue to innovate and optimize this technology, the applications and implications of brass cage integration are poised to expand further, shaping the future of industrial machinery and setting new benchmarks for excellence.

6 Conclusion

In conclusion, the integration of brass cages in spherical roller bearings marks a significant milestone in the evolution of industrial machinery and equipment.

The adoption of brass cage integration has redefined industry standards by elevating the efficiency, reliability, and performance of spherical roller bearings. With their superior strength, durability, and heat resistance, brass cages offer unparalleled advantages over traditional steel cages, setting new benchmarks for quality and longevity in bearing assemblies.

This transformative technology has far-reaching implications across diverse industries, from automotive and aerospace to heavy machinery and manufacturing. Case studies have illustrated the tangible benefits of brass cage-integrated bearings, demonstrating improved operational efficiency, reduced maintenance costs, and enhanced reliability in real-world applications.

As we look to the future, it is imperative for industry stakeholders to embrace and further explore the potential of brass cage integration. By investing in research, development, and implementation of this innovative solution, companies can stay ahead of the curve and remain competitive in an ever-evolving landscape.

In essence, brass cage integration in spherical roller bearings represents not just a technological advancement, but a paradigm shift that promises to shape the future of industrial machinery. It is a call to action for manufacturers, engineers, and decision-makers to embrace innovation, drive progress, and redefine industry standards for generations to come. Together, let us embark on this journey towards elevated efficiency, reliability, and excellence in industrial manufacturing.

7 FAQs: Common Questions About Spherical Roller Bearings/Brass Cage

1. What are Spherical Roller Bearings?

Spherical roller bearings are specialized bearings designed to accommodate high radial and axial loads in applications where misalignment or shaft deflection is present. Unlike other types of roller bearings, spherical roller bearings have a spherical outer raceway, allowing for smooth rotation and reduced friction even under challenging operating conditions.

2. What is a Brass Cage and Why is it Used in Spherical Roller Bearings?

A brass cage is a structural component of spherical roller bearings that holds the rolling elements in place and maintains their proper alignment. Brass cages offer several advantages over traditional steel cages, including superior strength, heat resistance, and corrosion resistance. Additionally, brass cages contribute to reduced friction and improved lubrication efficiency, resulting in enhanced performance and longevity of the bearings.

3. How Does Brass Cage Integration Improve Efficiency in Spherical Roller Bearings?

Brass cage integration in spherical roller bearings leads to elevated efficiency by reducing weight and friction within the bearing assembly. The lighter weight of brass cages reduces inertia and energy consumption, resulting in smoother operation and improved overall efficiency of machinery and equipment. Additionally, brass cages facilitate better heat dissipation and lubricant distribution, further enhancing performance and reliability.

4. Are Spherical Roller Bearings with Brass Cages Suitable for High-Temperature Applications?

Yes, spherical roller bearings with brass cages are well-suited for high-temperature applications due to the excellent heat resistance of brass. Brass cages can withstand elevated temperatures without deforming or losing their structural integrity, making them ideal for use in industries such as steelmaking, papermaking, and mining where operating temperatures can be extreme.

5. How Does Brass Cage Integration Impact Maintenance Requirements and Lifecycle Costs?

The integration of brass cages in spherical roller bearings can lead to reduced maintenance requirements and lifecycle costs. Brass cages exhibit superior durability and resistance to wear, resulting in longer bearing lifespan and reduced downtime for maintenance and replacement. Additionally, the enhanced lubrication efficiency provided by brass cages helps prolong bearing life and minimize the need for frequent relubrication, further reducing maintenance costs over time.

In conclusion, spherical roller bearings with brass cages offer numerous advantages in terms of efficiency, reliability, and performance. By addressing common questions and concerns about brass cage integration, industry stakeholders can make informed decisions and leverage this innovative technology to redefine industry standards and drive progress in industrial manufacturing.